INDUSTRIES

Trusted across sectors for smart manufacturing solutions.

Do you have complex specs, tight timelines, and strict regulatory standards? That’s our specialty!

From complete machines and factory tooling to automated processes and systems that move production forward, Bent River is ready to take on your toughest challenges.

Defense

Mission-critical manufacturing that holds the line.

Need reliable Ground Support Equipment (GSE) or factory automation for defense production? We design and deliver rugged, integrated systems that support missile assembly, advanced aviation, smart defense, and beyond — with speed, precision, and full compliance.

-

Your most sensitive and secure projects are in the right hands.

ISO 9001:2015 certified

ITAR registered

NIST 800-171

CMMC 2.0 certified

AS9102 Rev C

-

Mechanical-electrical design, build, assembly, and integration for all types of GSE equipment including:

Rings, cradles, and carts

Precision alignment tools and fixtures

Assembly, inspection, and testing fixtures

Automated guided vehicle integration

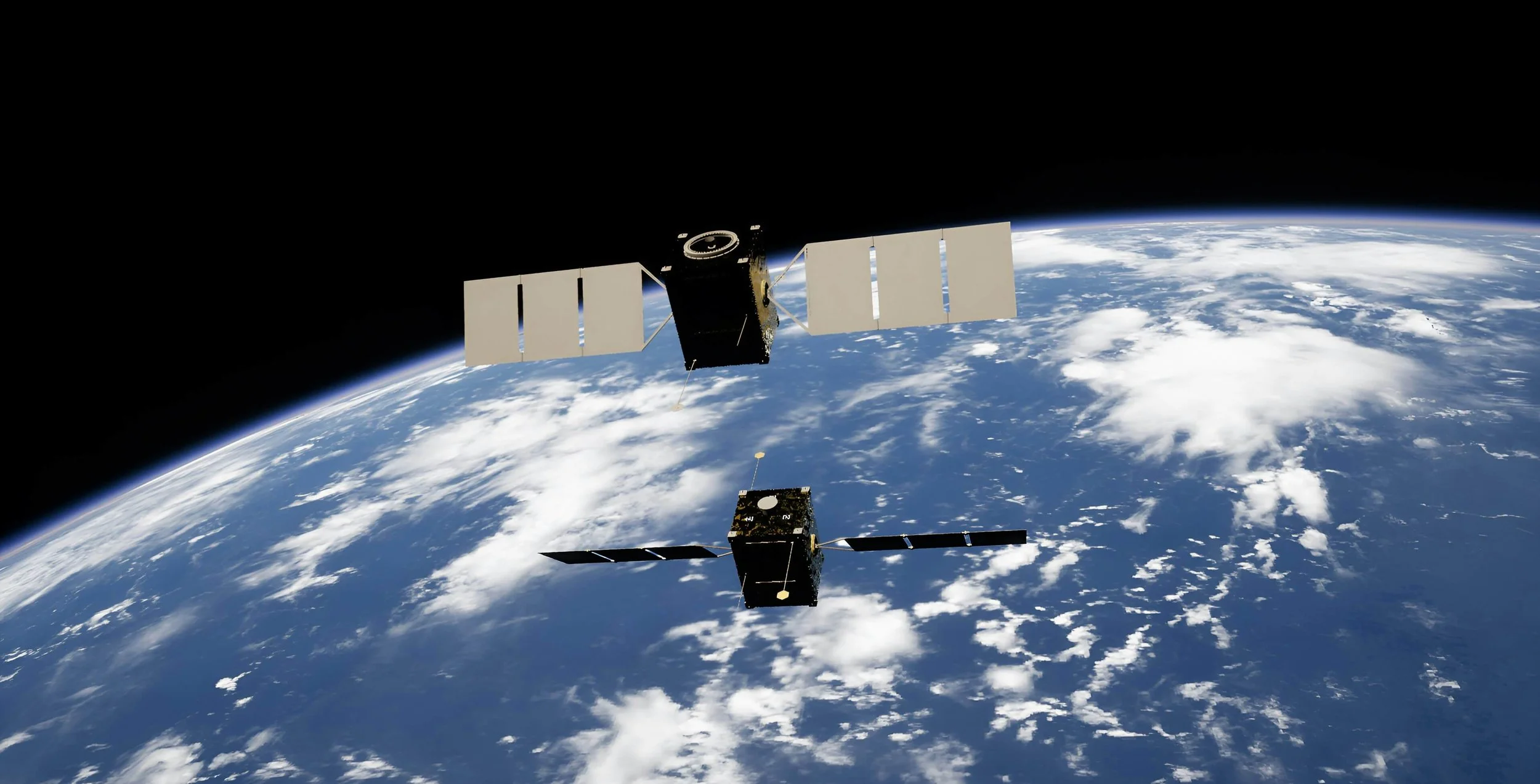

Space

Over 90% of the satellites in orbit today use solar panels laminated on a Bent River machine.

Space product manufacturers need a partner who understands how to develop and scale production processes for space-grade solar. At Bent River, we help you move from prototype to production with precision, speed, and technical fluency.

No other industry moves faster—and we’re built for it.

-

Your most sensitive and secure projects are in the right hands.

ISO 9001:2015 certified

ITAR registered

NIST 800-171

CMMC 2.0 certified

AS9102 Rev C

-

Solar panel prototypes

Custom lamination systems

Manufacturing process development

Lights-out, automated production systems

CASE STUDY: 90% REDUCTION IN PRODUCTION TIME

A satellite manufacturer came to us with a bottleneck: producing space-grade solar panels took over three hours per unit. Our team developed semi- and fully-automated tooling and fixtures that cut takt time to just 14 minutes.

Result: A 90% reduction in takt time while maintaining quality.

Aerospace

Need tooling or subassemblies for products that fly?

Aerospace demands precision, speed, and a manufacturing partner who can meet your standards and delivery times. At Bent River, we help you meet tight tolerances with full-scope tooling and automation support.

-

Your most sensitive and secure projects are in the right hands.

ISO 9001:2015 certified

ITAR registered

NIST 800-171

CMMC 2.0 certified

AS9102 Rev C

-

Mechanical-electrical assemblies

Ground support and calibration hardware

Factory tooling and automation systems

Material handling and testing equipment

Technology

Innovation moves fast–we keep you on the forefront.

With decades of prototyping and automation experience, Bent River helps tech companies accelerate development, iterate with precision, and scale smarter.

Whether you’re building inspection systems, test rigs, or production-ready equipment, our team delivers custom solutions fast—without sacrificing quality or adaptability.

-

Prototyping & Engineering – Fast-turn, high-accuracy builds informed by decades of cross-industry experience.

Custom Tooling & Fixtures – Built to spec for inspection, packaging, post-processing, and more, with tight tolerances and high repeatability.

Automation & Integration – Scalable systems for parts handling, inspection, and machine automation.

OEM Contract Manufacturing – Secure, flexible production support from alpha to rollout.

Material Strategy & Process Planning – Long-lead sourcing and smart scheduling to keep your projects on track.

CASE STUDY: CURVED PANEL FOR SOLAR ELECTRIC CAR

Aptera was using aluminum thermoformed molds and vacuum bags to produce exterior panels of their solar electric car for proof of concept. But to scale for production, they needed a new process—and a partner who could help them get there. That’s when they came to us.

Result: A curved solar panel that was road-worthy.

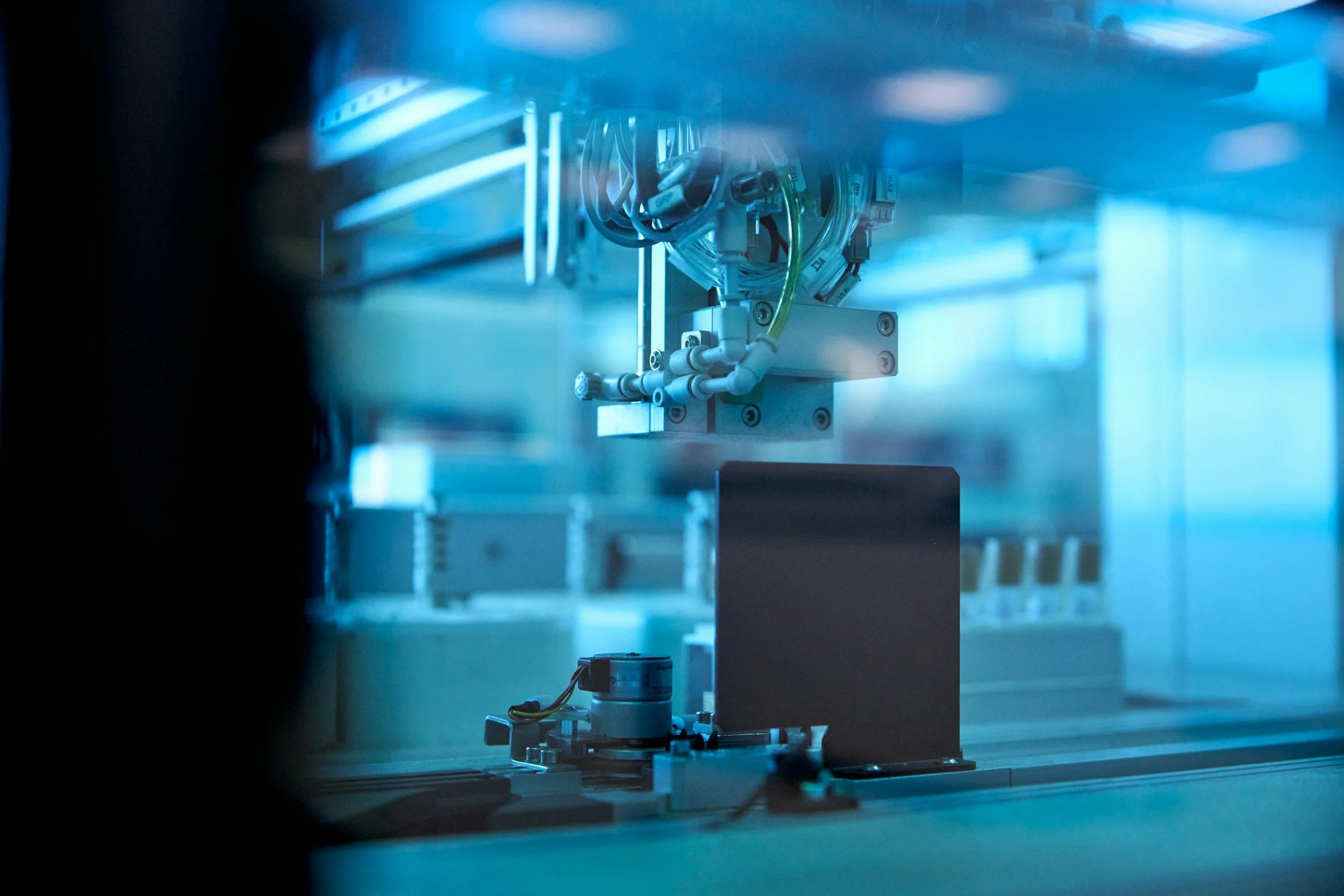

Semiconductor

Testing equipment and material handling solutions.

Semiconductor manufacturing leaves no room for error. With over 40 years in the industry, we build semiconductor testing and handling systems that meet tight specs and tighter timelines.

We specialize in functional, structural, and parametric testing equipment—designed to integrate with your process and deliver consistent, high-quality performance.

-

Functional, structural, and parametric test equipment

Automated wafer inspection and material handling systems

Mechanical-electrical integration and subassembly optimization

Flexible tooling for custom product configurations

OEM manufacturing support with weekly production coordination

CASE STUDY: MODULAR UPGRADE FOR CHIP INSPECTION

Sonix came to us for a more flexible approach to building their AutoWafer inspection systems. We collaborated to redesign key subassemblies for modularity—so one machine could be easily reconfigured for different inspection tasks.

Result: Faster changeovers, cost-effective production, and better ability to support the world’s leading chip manufacturers.

Medical

Precision manufacturing for regulated environments.

From prototyping to production systems, Bent River helps medical OEMs build the tools and equipment behind safer, more efficient care. We know what’s at stake in medical manufacturing.

Our team works closely with yours to ensure quality, traceability, and compliance from start to finish—backed by ISO 9001 certification and deep experience with FDA-regulated standards.

-

FDA CFR 21 QSR and ISO 9001:2015 expertise

Proven quality processes and SOPs for regulated production

Full documentation for repeatability and regulatory readiness

-

Medical device assembly automation

Custom filling and packaging systems

OEM sub-assemblies (mechanical + electrical)

Case packing and palletizing

Specialized fixtures and test equipment

Automated equipment for assembly, packaging, and inspection

Find out how we can help you.