SERVICES

Custom manufacturing solutions—engineered around your needs.

From prototypes to full production systems, we bring deep expertise to every phase of your project—design through final assembly—with fewer handoffs and no surprises.

How We Work

A clear path from idea to installation.

When you bring us a challenge, we don’t just quote parts — we help you think through the system. Whether you're refining an existing design or starting from scratch, our process guides you from early concept to final install with consistent communication, documented checkpoints, and expert oversight at every stage.

Each engagement is a little different — but most follow a similar path.

The engineers who built your system stay with you after install — ready to fine-tune performance or support your next build.

We start by understanding your product goals, technical constraints, and regulatory requirements, including site visits and working through edge cases.

1. Discover & Define →

Parts are machined in-house and with vetted partners. Our team adapts quickly to design changes and maintains open lines of communication throughout.

2. Concept & Specify →

Once we understand what success looks like, we generate initial concepts and deliver a detailed proposal outlining scope, timeline, and budget.

4. Fabricate & Build →

We handle both mechanical and electrical assembly in-house — including PLCs, HMIs, and pneumatics — so your system is built and tested before it ever hits your floor.

5. Assemble & Integrate →

Our engineering team develops a full design package — from CAD drawings and BOMs to control logic plans. We use proven building blocks for speed and reliability, and tailor everything to your specs

3. Design & Doc →

Final systems are validated through FAT/SAT testing. We train your team, tune for usability, and support installation — so you can hit the ground running.

6. Test, Train, & Deliver →

OEM Contract Manufacturing

Your product. Our precision. One seamless build.

When your core expertise is in software, instrumentation, or tech innovation, it helps to have a partner who knows hardware inside and out. At Bent River, we design, fabricate, and assemble the mechanical systems behind complex products—motion, controls, structure, and fit-up—so your team can focus on functionality and market success.

Whether you need a single build or ongoing production support, we deliver precision hardware that integrates seamlessly with your technology.

-

Have a limited engineering department

Lack access to the latest manufacturing methods

Face internal red tape that slows speed to market

Need a partner who prioritizes confidentiality

Value nimble, ISO-certified product development tailored to your specs

Factory Tooling & Ground Support Equipment

Custom-built tools that keep your production moving.

When your process demands more than off-the-shelf, we design and build custom mechanical tooling to match your exact process requirements. From lift rigs to wrenches, every tool is engineered for durability, precision, and ease of use on the floor.

Whether you need to move, hold, align, or support a critical part, our tooling delivers repeatable results in demanding production environments and industries.

-

Hand tools and fixtures

Mechanical jigs and alignment tools

Carts, cradles and lift rigs

Pallet elevators (500–6,000 lb. capacity)

Complete custom builds

Custom Automation Equipment

Purpose-built machines that boost productivity.

When your process requires a unique solution, we engineer and deliver custom automation tailored to your operation. Our systems are designed for speed, repeatability, and long-term maintainability.

-

Complete automation cells and conveyor systems

Vision and quality control integration

Automated material handling and packaging

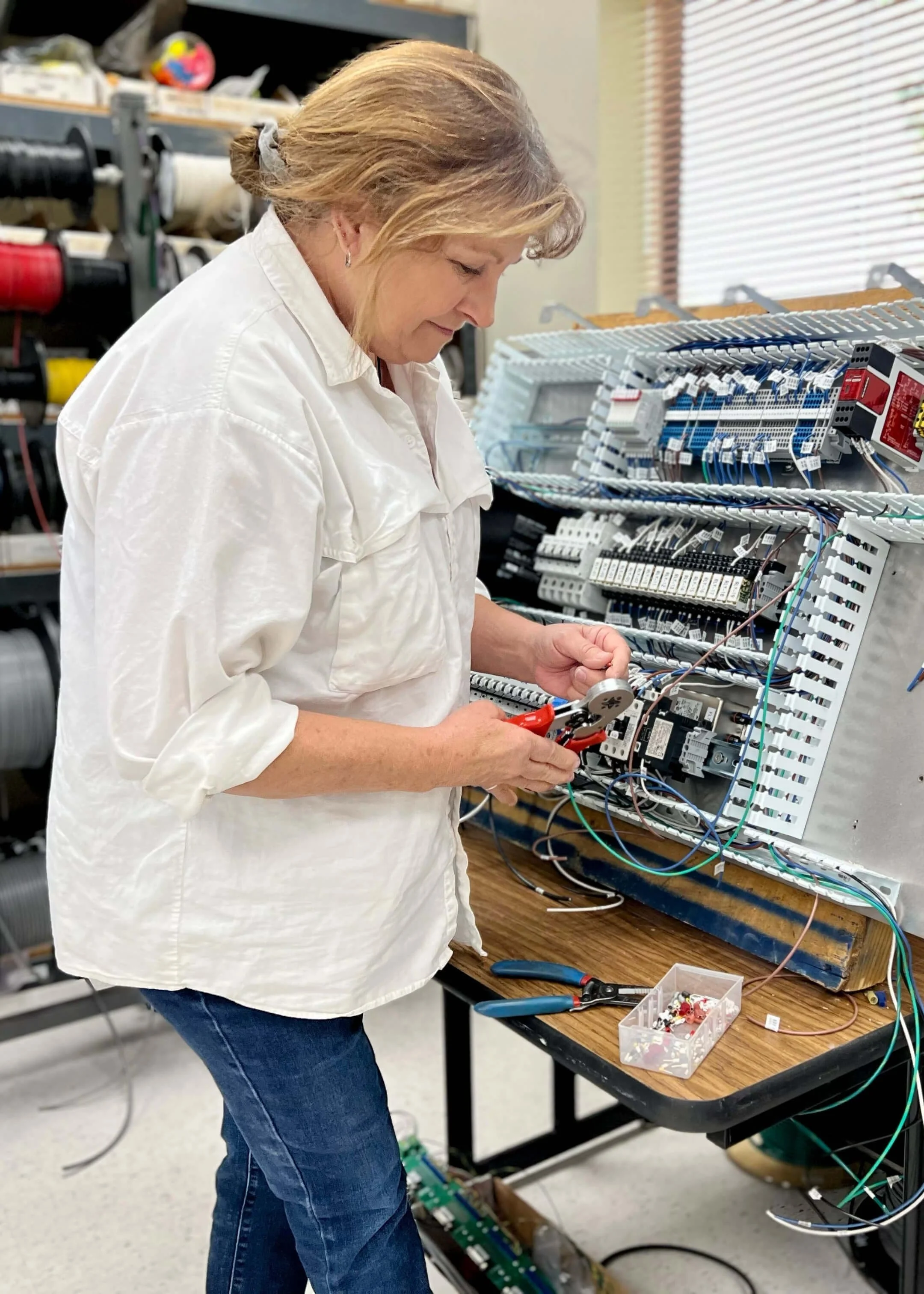

Systems Integration & Controls

Integrated systems that just work—end to end.

When you're combining robotics, sensors, controls, and communication, there’s no room for error. We bring it all together into one seamless system—designed to hit your performance goals and adapt to real-world production.

Whether you're launching a new line or revamping an existing one, our team focuses on throughput, uptime, and long-term flexibility.

-

Fully integrated robotics, PLCs, sensors, and SCADA

Custom control panels with clean documentation and labeling

Programming and debug support

Operator training, documentation, and validation

Lamination Systems & Process Development

Precision lamination, engineered for repeatability.

When consistency matters, our panel laminators deliver. Built for production and R&D teams, these systems give you full control over pressure, temperature, vacuum, and dwell—so you can hit your process targets, batch after batch.