Bent River Machine Laminator

Our laminators provide solutions to organizations doing research and development in numerous industries including Solar, Materials, LED, Optics, Glass, Coatings, Fabrics, Film, and Flat Panel Display Industries.

Some of the common problems that our laminators can help you overcome are:

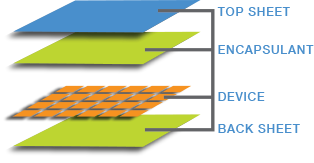

- Inconsistent process stability and lamination results

- Air entrapment in the lamination layer

- Poor lamination allowing delaminating to occur

- Inconsistent pressure on the panel causing cracking or damage

- Wrinkling or deformation of the lamination layers creating irregular appearance and performance

Laminators Designed with Experimentation in mind.

- Touch-Screen Control System

- Precision control of Temperature, Pressing Force, Time, and Vent

- Switch to Production Mode to run a recipe repeatedly

- Unique lift pin system allows chamber to reach vacuum prior to applying heat to product

- Customization to meet specific size and process requirements

Three Standards Sizes*

*We also have the ability to build custom sizing and modifications based on your organization’s needs.

*We also have the ability to build custom sizing and modifications based on your organization’s needs.Demo The Laminator

Do you think one of our laminators might be a solution for you? Watch our video demo or come demo a laminator at our facility to see how our laminator can help you with your process!

Have a question?

Call Us 928.634.7568 or Send Us An Email